Our Blogs

How Dual Girder Construction Enhances Stability in Circular EOT Cranes

Introduction

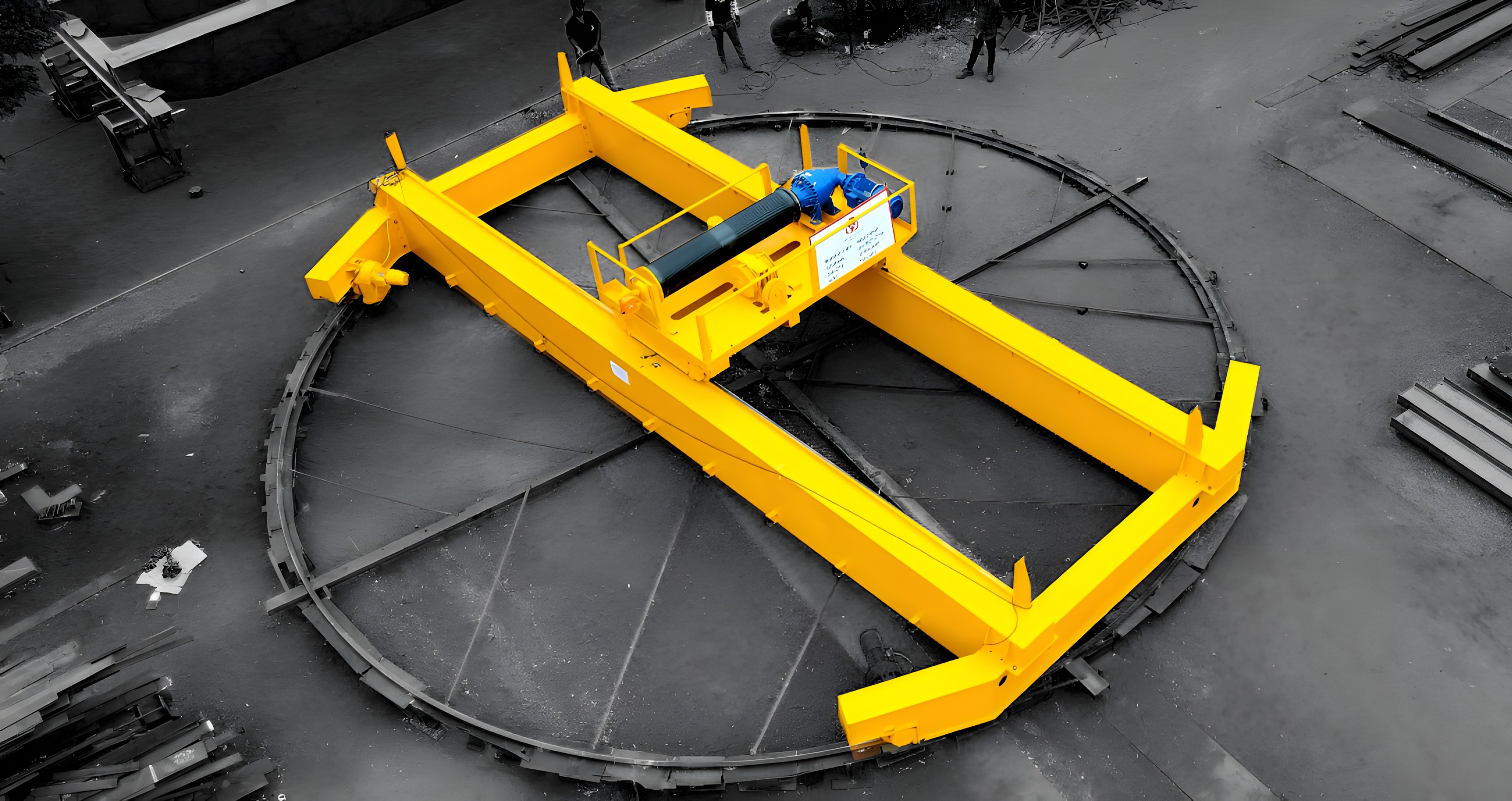

At Mega Cranes, we design heavy-duty lifting solutions that meet the complex requirements of industries operating in circular structures such as wells, pits, and specialized plant layouts. Our Double Girder Circular EOT Cranes are engineered for smooth rotation, high load handling, and long-term reliability. A key factor behind their superior performance is the dual girder construction, which significantly improves crane stability and operational safety.

What Is Dual Girder Construction in Circular EOT Cranes?

Dual girder construction means the crane uses two parallel main girders to support the hoist and trolley system. The hoist travels between these girders, keeping the load centrally positioned while moving along a circular track. This design allows the crane to handle higher capacities, typically ranging from 5 to 100 tons, making it ideal for demanding industrial lifting operations.

Mega Cranes designs these systems to ensure smooth movement along curved paths while maintaining structural balance.

Better Load Distribution and Reduced Structural Stress

One of the biggest advantages of dual girder construction is even load distribution. Instead of concentrating weight on a single beam, the load is shared across both girders. This reduces bending stress, minimizes deflection, and improves the overall strength of the crane structure.

Lower structural stress also means reduced wear on wheels, rails, and mechanical components, leading to longer service life and lower maintenance costs.

Enhanced Stability During Circular Movement

Circular EOT cranes operate on curved tracks, where lateral forces and rotational motion can cause instability if the structure is not rigid enough. Dual girder construction provides greater resistance to torsional forces, reducing sway and vibration during crane travel.

Circular EOT cranes operate on curved tracks, where lateral forces and rotational motion can cause instability if the structure is not rigid enough. Dual girder construction provides greater resistance to torsional forces, reducing sway and vibration during crane travel.

Greater Height and Span Capabilities

Double girder circular cranes can support larger spans and higher lifting heights compared to single girder systems. With spans up to 50 meters and lifting heights reaching 75 meters, Mega Cranes’ circular EOT cranes are suitable for large industrial facilities where vertical and radial coverage is essential.

This flexibility helps improve material flow and supports efficient plant operations.

Reliable Performance in Harsh Industrial Conditions

Mega Cranes designs circular EOT cranes for both indoor and outdoor applications, capable of operating in ambient temperatures up to 45°C. The rigid dual girder structure improves durability, reduces vibration-related damage, and ensures consistent performance even in continuous-duty environments.

Conclusion

Dual girder construction plays a crucial role in enhancing the stability, strength, and safety of circular EOT cranes. With superior load distribution, smoother circular movement, and higher capacity handling, Mega Cranes’ Double Girder Circular EOT Cranes provide reliable lifting solutions for heavy industrial applications. Choosing the right crane design ensures safer operations, improved productivity, and long-term operational efficiency.